Miniature couplings from SDP/SI

We have a very wide range of small and miniature couplings from SDP/SI StockDrive. Find the right coupling for building a suitable solution within the precision industry.

Miniature couplings for endless applications

SDP/SI Stockdrive offers a wide range of miniature or small couplings. SDP/SI is a renowned brand when it comes to couplings for the precision industry. The wide range and endless possibilities of the different types of couplings from SDP/SI offer a suitable solution for every application.

Need help selecting the right coupling for your application? Please feel free to contact us and we will be happy to assist you.

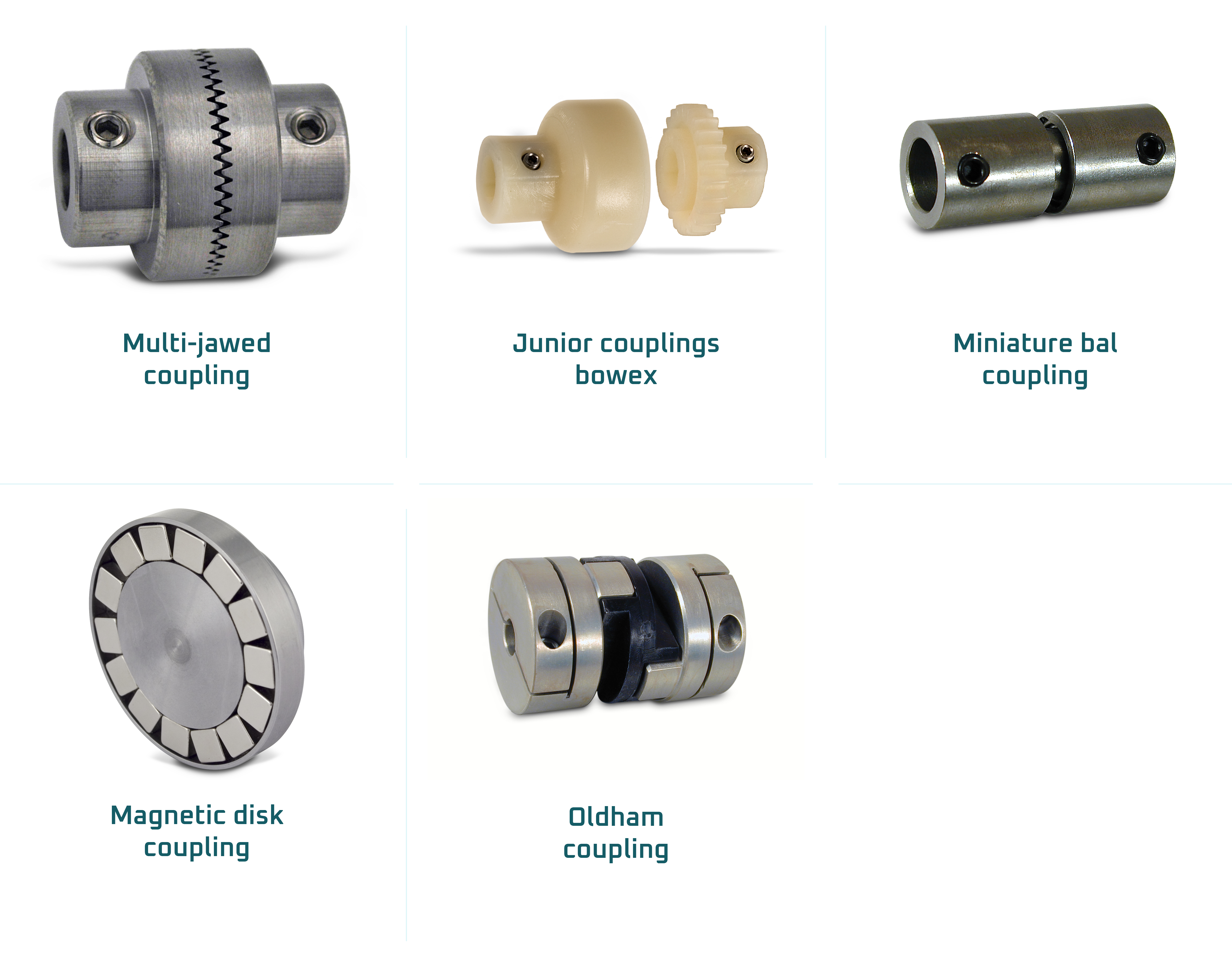

Products

Here you can find an overview of all the different couplings from SDP/SI Stockdrive that we have in our product range.

-

Flexible disk couplings

These compact flexible disc couplings have an extended torque range and good performance. The compact design offers torques from 0.6 to 12 Nm. Device manufacturers can benefit from the smaller size and lower weight, while getting more torque capacity and power. As a high-performance coupling for motion control, disc couplings are well suited for applications requiring precise positional accuracy.

Materials Stainless steel, Aluminum Bore 3mm – 12mm Outside diameter 15mm – 39mm Length 16.5mm – 32.8mm -

Flexible helical couplings

SDP/SI bellows couplings are flexible couplings designed for different types of loads. SDP/SI Hi-Flex bellows couplings are used for applications that combine high shaft alignment with low radial loads on the bearings. SDP/SI modular bellows couplings are configurable and offer high torsional stiffness for fast torque transfer. A wide variety of bores and combinations are offered to meet specific needs.

Materials Brass, Bronze, Stainless steel, Nickel, Steel, Aluminum, Neoprene, Nylon, Zinc BoreBore 0.0625 inch (1mm) – 1.750 inch (45mm) Outside diameter 0.250 inch (6.4mm) – 3.700 inch (94mm) Length 0.480 inch (14.2mm) – 3.55 inch (90.3mm) -

Precision bellows couplings

SDP/SI spiral couplings are a type of flexible coupling for axial movement, angular rotation and parallel offset. This coupling has one-piece construction, so there is no backlash. The coupling is made flexible by removing material from the piece in a spiral pattern. SDP/SI spiral couplings are available in aluminum and stainless steel.

Materials Aluminum, stainless steel, steel Bore 0.094 inch (2mm) – 1.00 inch (12mm) Outside diameter 6.35 mm (1/4 inch) – 31.8 mm (2 1/4 inch) Length 0.37 inch (20mm) – 3.50 inch (58mm) -

Hub bellow couplings

Flexible Couplings can compensate for shaft misalignments and are designed for different types of loads. No single type of coupling can provide a universal solution to all coupling problems; therefore, many designs are available, each with construction features to meet one or more application requirements. SDP/SI offers many styles of flexible couplings, such as bellows couplings, screw couplings, Oldham couplings, universal joints and flexible shafts.

Matériaux (inclure) Aluminum, Stainless, Steel, Resin, Brass, Bronze, Steel, Iron, Nickel, Copper, Polymer, Rubber, Acetal, Neoprene, Nylon, Zinc, Silicone, Polyurethane, Polyimide, Polyethylene, Fiberglass Bore 0.0625 inch (1mm) – 1.750 inch (45mm) Outside diameter 0.25 inch (6,4mm) – 3.70 inch(94mm) Length 0.375 inch (7mm) – 3.55 inch (90.3mm) -

Flexible anti-vibration couplings

For positional accuracy and vibration reduction in a servo system . These couplings solve alignment errors. For servo systems for semiconductor manufacturing equipment industry, scanning equipment and other automation applications.

Standard sizes available in bores from 3 to 16 mm. Can also be customized.

Materials Aluminum, Steel, Rubber Bore 3 mm – 16 mm Outside diameter 15 mm – 39 mm Length 18 mm – 55 mm -

Junior couplings bowex

Two- and three-piece Junior couplings are curved gear couplings made of nylon. Designed to compensate for axial, radial and angular misalignments, they are lightweight and maintenance-free.

Materials Nylon Bore 6 mm – 20 mm Outside diameter 40 mm – 52 mm Length 48 mm – 56 mm -

Magnetic disk coupling

A magnetic coupling transfers torque by using a magnetic field rather than a physical mechanical connection. Because a non-contact magnetic connection is created between the two shafts, these couplings are typically used for liquid pumps and screw systems where seals wear or break over time as the two surfaces slide against each other.

Materials Stainless steel, steel, nickel Bore 0.125 inch(5mm) – 1.000 inch (19mm) Outside diameter 1.06 inch (27mm) – 2.86 inch (73mm) Length 0.63 inch (15mm) – 1.00 inch (25,4mm) -

Miniature bal coupling

Materials Stainless steel, Nylon Bore 0.0625 inch (2mm) – 0.6250 inch (16mm) Outside diameter 7/32 inch (5.6mm) – 1.0 inch (25.4mm) Length 5/8 inch (15.9mm) – 1 7/8 inch (47.6mm) -

Multi-jawed coupling

SDP/SI Precision Multi-jawed Coupling is a rigid coupling that can handle minimal shaft alignment. The helical gear coupling allows a positive connection between two shafts that can be disconnected or coupled at any time at standstill.

Materials Stainless steel Bore 0.1248 inch – 0.2498 inch Outside diameter 0.75 inch Lengte 0.87 inch -

Oldham coupling

An Oldham coupling consists of three parts: a hub connected to the input shaft, a hub connected to the output shaft, and a floating member connected to the first two by tongue and groove in the center of the coupling. The tongue and groove of one side are 90° or perpendicular to the tongue and groove of the other side. The input and output shafts rotate at the same speed as the center member, about its center point. Twice per revolution, the center point travels a circular path around half of the input and output shafts. To prevent backlash, springs are usually used.

Oldham couplings can accommodate lateral shaft misalignment of up to 10% of the nominal shaft diameter and angular misalignment of up to 3°. Lubrication can be a problem, but in most applications this can be solved by choosing a coupling that uses a wear-resistant plastic or elastomer member instead of steel or bronze floating members.

Materials Stainless steel, Aluminum, Acetal, Brass Bore 0.125 inch (2mm) – .5625 inch (12mm) Outside diameter 0.25 inch (6.4mm) – 1.62 inch (41,1mm) Length 0.50 inch (12,7mm) – 2.00 inch (50.8mm) -

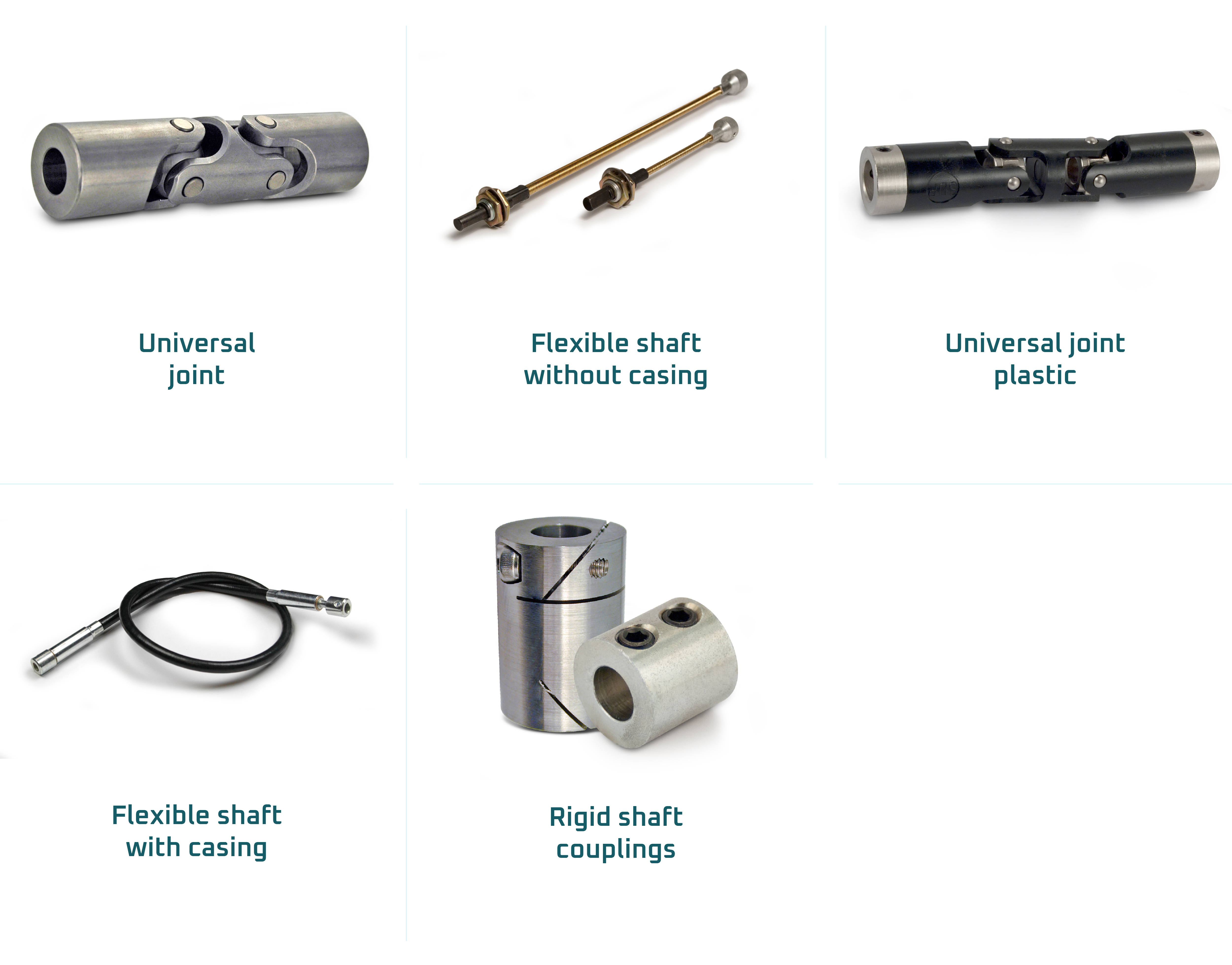

Rigid shaft couplings

Rigid couplings have limited applications unlike flexible couplings. Rigid couplings cannot compensate for shaft misalignments and are therefore used when shafts are already in precise lateral and angular alignment. Because of their simple and robust design, rigid couplings can generally transmit more power than similar-sized flexible couplings.

Materials Stainless steel, Acetal, Aluminum, Steel, Brass Bore 0.09 inch (0.8mm) – 0.50 inch (15.0mm) Outside diameter 0.125 inch (7mm) – 0.53 inch (27mm) Length 0.21 inch (7mm) – 1.00 inch (38mm) -

Flexible shaft with casing

If polyurethane timing belts are preferred because of weight (aluminum pulleys) or environmental variables, the endless spooled belts from Megadyne (Megapower) or Elatech (iSync) are the solution.

Materials

Bronze, brass, steel Flexibele as Diameter 0.13 inch – 0.25 inch Length 24 inch – 48 inch -

Flexible shaft without casing

Materials

Stainless steel, steel Flexibele as Diameter 0.098 inch (1.7mm) – 0.250 inch (6,4mm) Length 3 inch (50mm) – 14 inch (355mm) -

Universal joint

Single and double universal joints made of stainless steel and alloy steel are offered in various bore sizes. Miniature universal couplings have no backlash, sealed lubrication and low inertia. Reverse universal couplings are small in size and light in weight at a given torque capacity. Telescopic units can be made from these couplings by combining them with miniature telescopic ball shafts.

Materials Stainless Steel, Steel, Zinc Bore 0.0938 inch (2.5mm) – 0.6250 inch (20mm) Outside diameter 3/16 inch (4.76mm) – 1 inch (32mm) Length 1 inch (25.4mm) – 7.30 inch (185mm) -

Universal joint plastic

Plastic universal joints are cost-effective, dampen vibrations, are electrically insulating and are well suited for low-torque applications. These joints are available in a wide variety of sizes and styles. It is also possible to manufacture connections according to specific requirements. Please contact us for this.

Materials Acetal Bore 1/8 inch (2mm) – 3/8 inch (10mm) Outside diameter 1/4 inch (6,3mm) – 5/8 inch (15.9mm) Length 3/4 inch (19mm) – 4 13/32 inch (111.8mm)

We like to share our thoughts with you

There is an optimal coupling for each specific installation. Finding the right coupling for your installation is therefore a matter of understanding the specifications and characteristics of your installation. Our experienced experts will be happy to ask you a few questions about your installation so that together we can find the optimal coupling.

Looking for technical support from our specialist?

Suppliers & Brands

Related Products

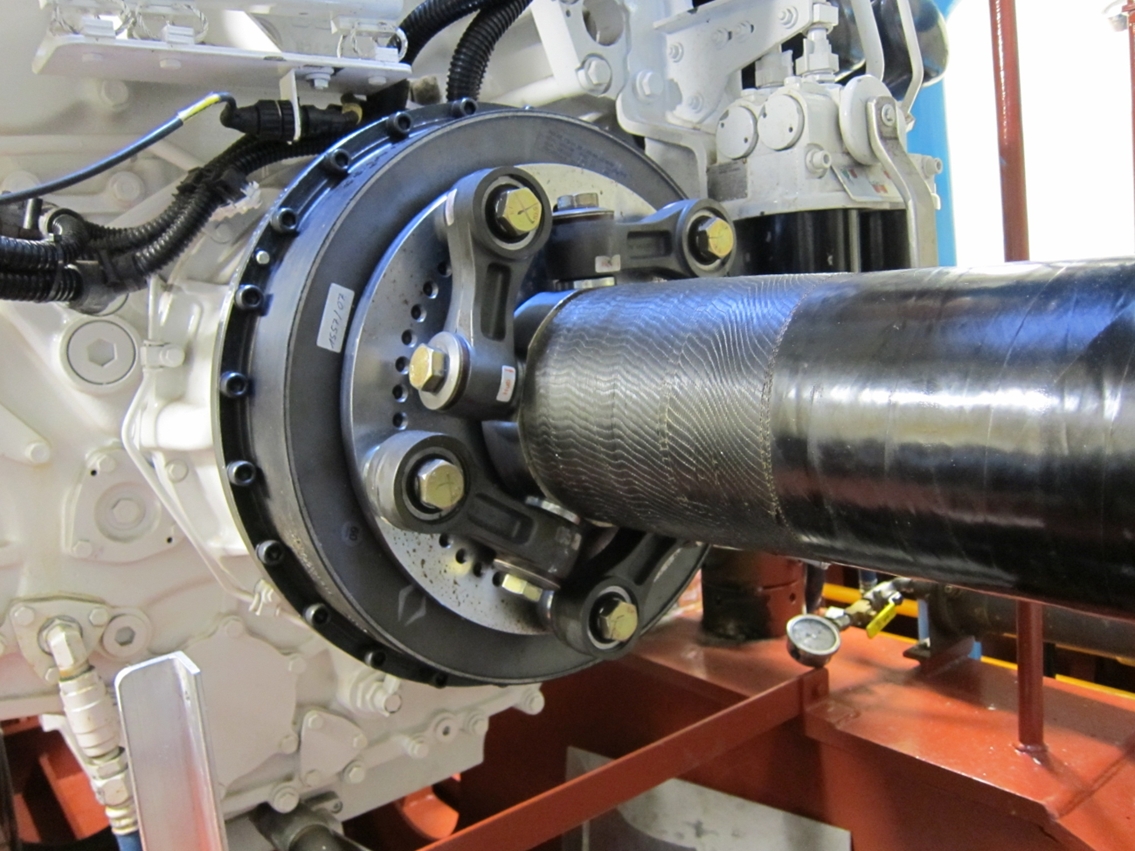

Couplings from Centa

Rigid Steelflex Couplings from Falk by Rexnord Regal

Bellows couplings from Rexnord Regal