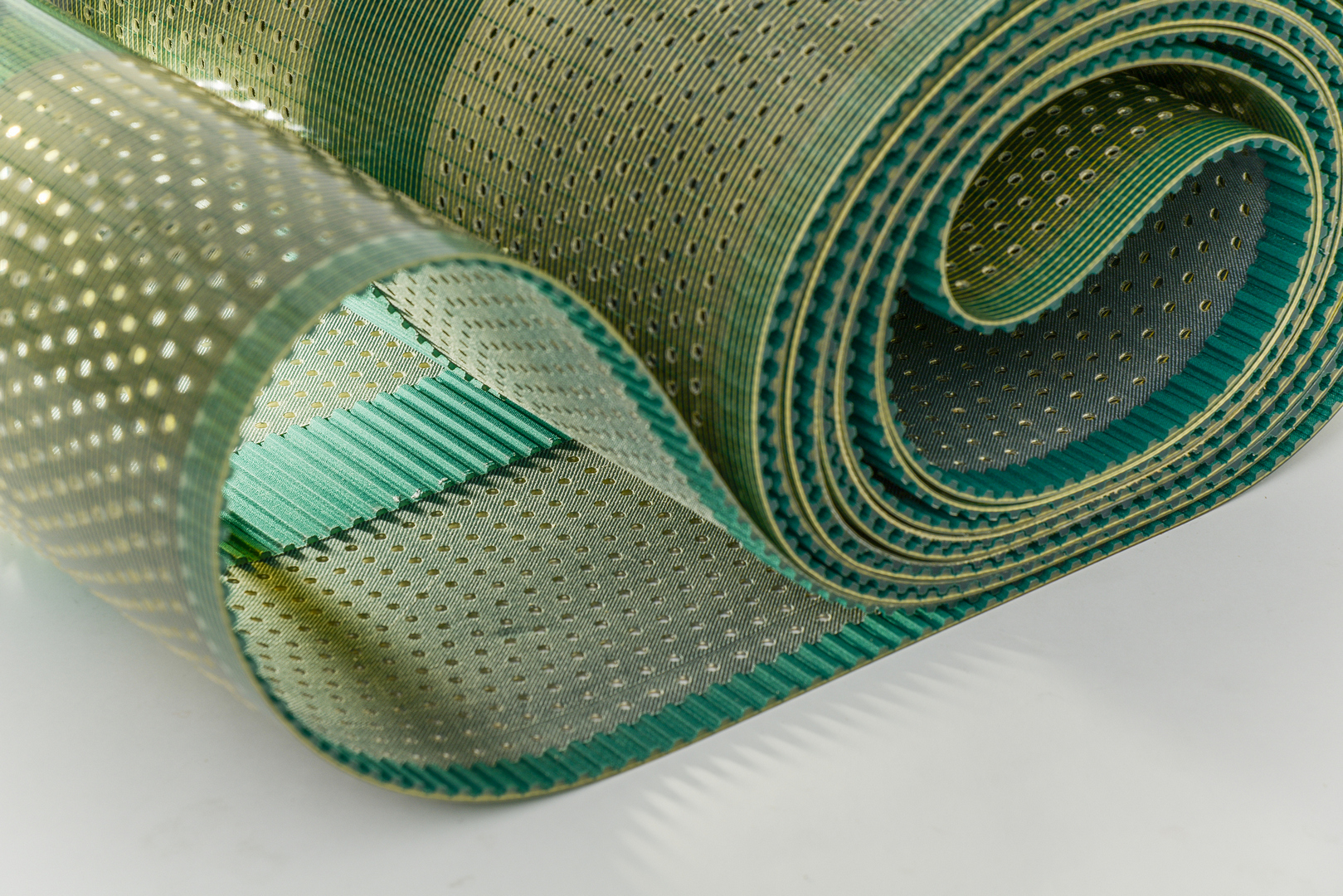

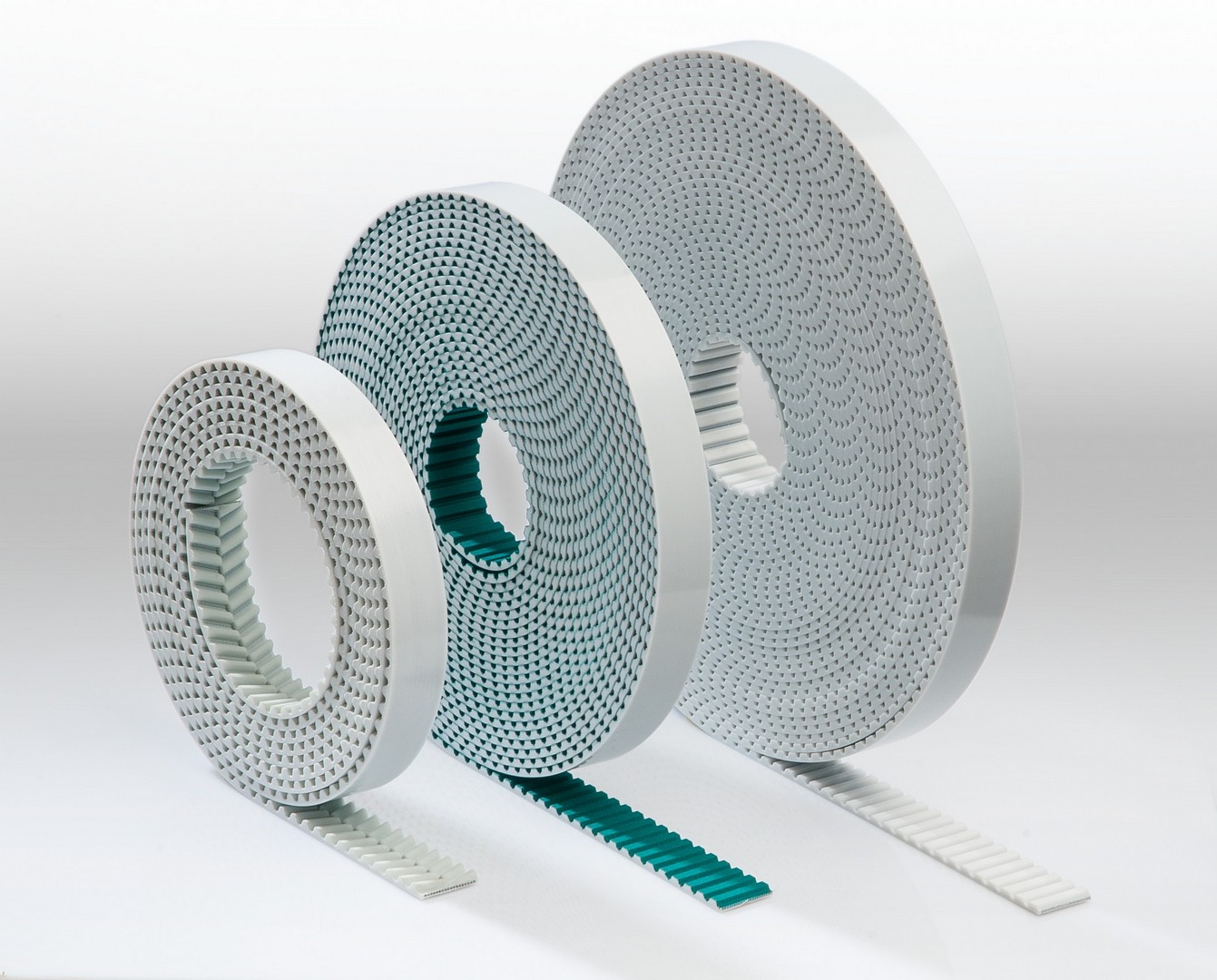

Vacuum belts

With a vacuum timing belt, products and packages can be fixed to the timing belt by vacuum. This is done by grinding a vacuum chamber into the timing belt. In this way, for example, lightweight products and packaging materials can be conveyed vertically and at high speeds with precision.

Important for a properly functioning vacuum belt

To arrive at the perfect vacuum timing belt for your specific application, we use our expertise in three areas, among others:

Minimal vacuum loss

By grinding the vacuum groove with high accuracy, we ensure minimum vacuum loss and thus optimum vacuum belt performance.

Furthermore, timing belts are available without a winding nose which limits additional vacuum loss.

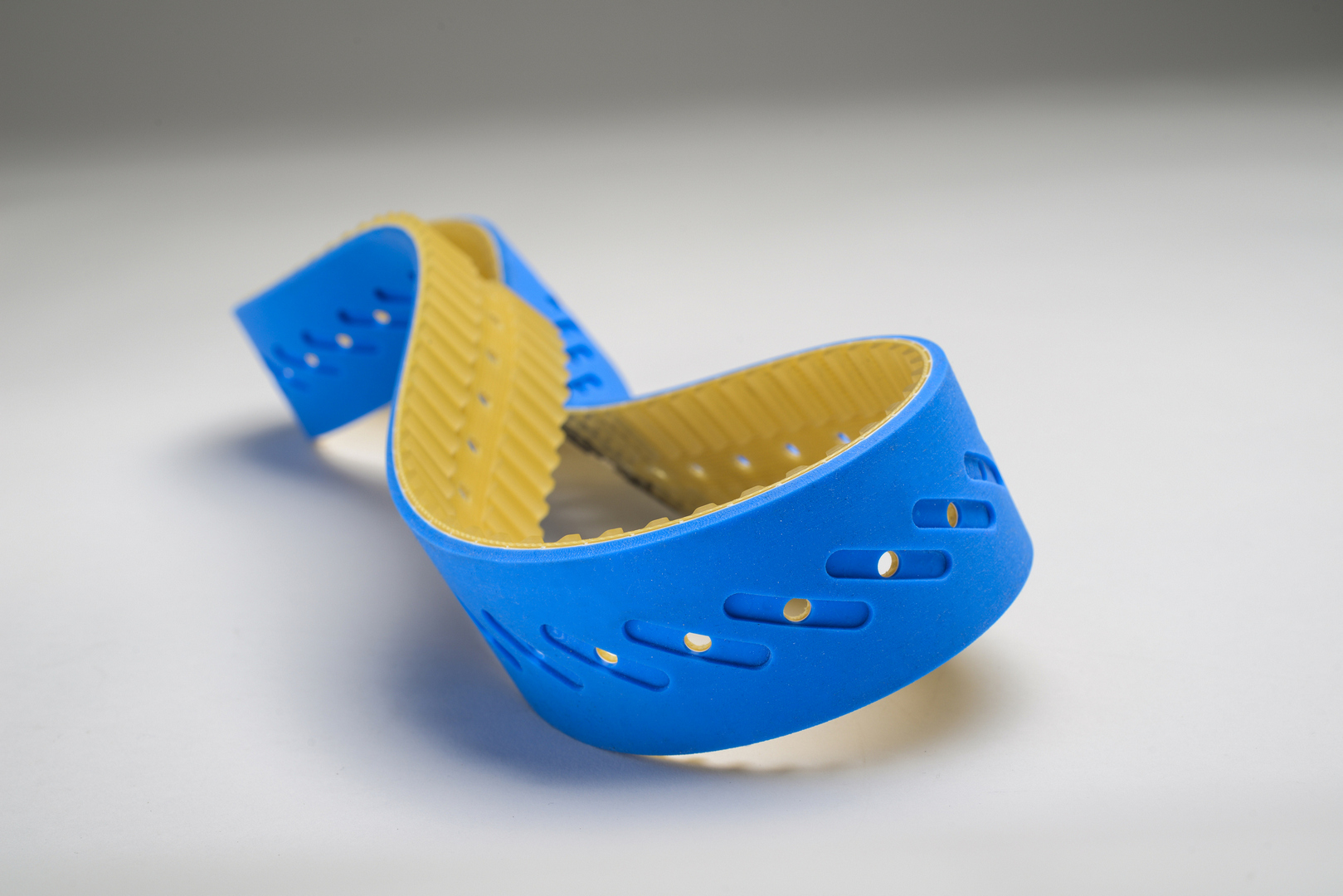

Wear-resistant coating

By applying an additional wear-resistant coating, we ensure that the timing belt has a long service life. Even when the timing belt is used intentionally or unintentionally as a friction belt.

Optimal grip

By selecting the right coating, we ensure that the timing belt has an optimal grip to the film or product to be conveyed. Examples of commonly used coating materials for vacuum belts include Linatex, Tenax, endless sprayed PU, silicone. For processing options and different properties of these coatings, please contact one of our specialists.

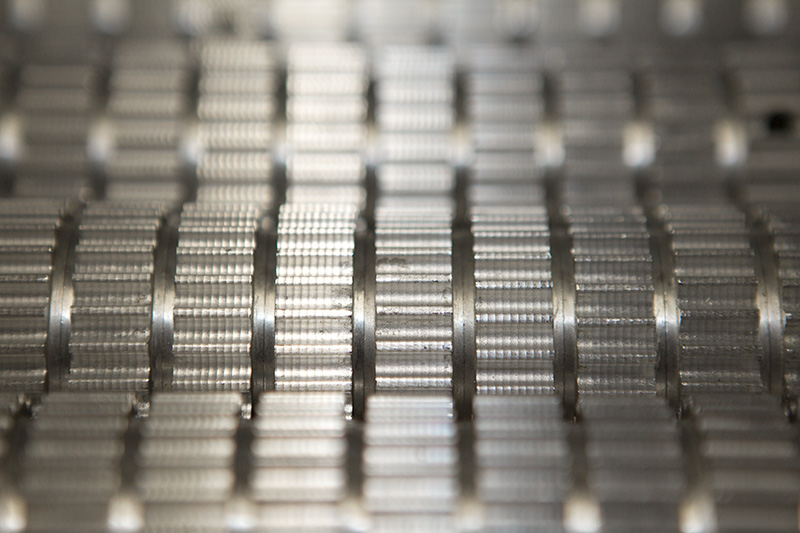

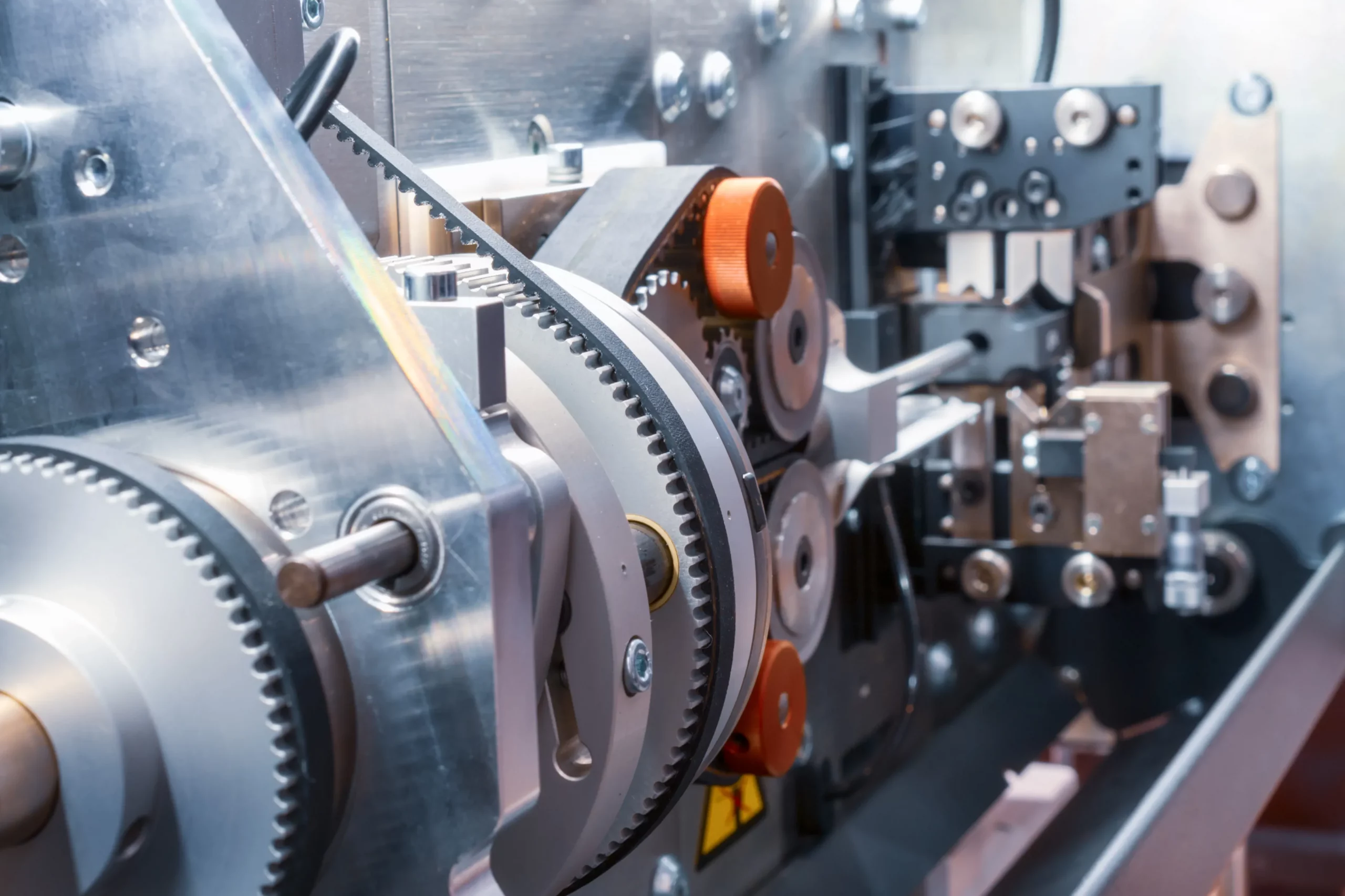

A pulley that fits perfectly

In our dedicated pulley production, we have the ability to produce the necessary vacuum pulleys as well. Thus, your pulleys are ready for immediate application and equipped with all the machining required for optimal performance and operation of your system.

Accuracies and tolerances of the timing belt pulleys are very important for minimum vacuum loss. In our in-house timing belt pulley production, we manufacture your pulleys to your specifications with the utmost care.

-

Technische specs

Type of tooth shape Basically all tooth shapes possible, most commonly used with timing belt is T10 Material pulleys Aluminum, Steel, Stainless steel Possible surface treatment pulley Chemical blackening, (hard) Anodizing, Chemical nickel plating, Phosphating Learn more about our in-house timing belt pulley production.

We are happy to work along with you

Finding the right timing belt transmission starts with understanding your issue. After all, there is an optimal configuration of timing belt and pulley for every application. By better understanding the intended use of the timing belt transmission, we can find the optimal solution for your issue within our endless range of timing belts and pulleys equipped with all possible machining.

Our experienced experts are ready to think with you.

Looking for technical support from our specialist?

Suppliers & Brands

Downloads

Related Products

Mechanical power transmission

Positioning

Conveying by timing belt

Special Timing Belt

Caldic Special Pulleys

Easy Drive Pulleys