Couplings from Centa

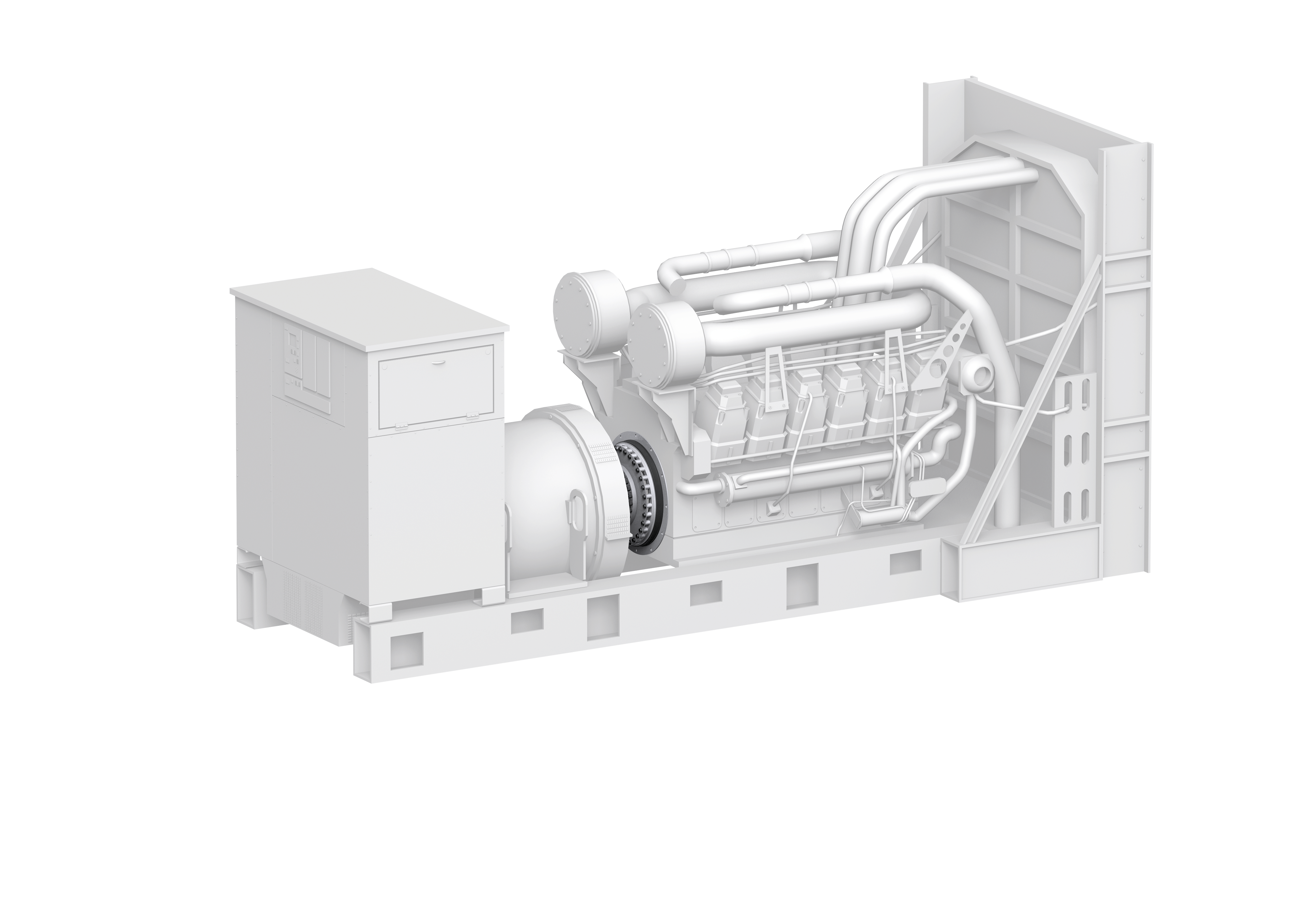

Centa’s couplings are designed to absorb vibration and are used in a variety of heavy-duty applications. Centa’s couplings are ideally suited for use in conjunction with STAMFORD generators supplied by Caldic Techniek Belgium.

Rigid and elastic couplings from Centa

Also, Centa’s high-quality couplings are used in other applications, such as agricultural machinery, marine propulsion, stone and concrete industries, pumping plants, heavy vehicles and wind turbines. Centa couplings are an excellent choice for absorbing vibrations to prevent damage to your equipment.

Rigid Couplings voor sub-critical installations

In case your installation has to work under the critical frequence of the drive, we call that a sub-critical installation.

In that case you can use a rigid coupling.

Elastical couplings for above-critical installations

In installations where the operating range is above the drive’s own frequency, we speak of above-critical installations. In such installations an elastic coupling is required to prevent damage to the installation.

Would you like to know more about the extensive possibilities of Centa couplings? Our experts will be happy to tell you more about the various products we can offer.

Products

Elastical Couplings from Centa

-

CENTAFLEX-A: versatile coupling with high elasticity

The CENTAFLEX-A forms the basis of the entire CENTA elastic couplings program. The design dates back to 1970 and is still leading the way worldwide. The applications are endless. The CF-A coupling is characterized by high elasticity in axial, radial and angular directions. Moreover, it is maintenance-free and has an unimaginable number of installation variants; in single form or double cardanic operation. The CENTAFLEX- A is suitable for almost any connection between floating and driven equipment.

- Simple, compact design.

- Low weight, low mass moment of inertia.

- High performance.

- High speed range.

- Large shaft bores possible.

-

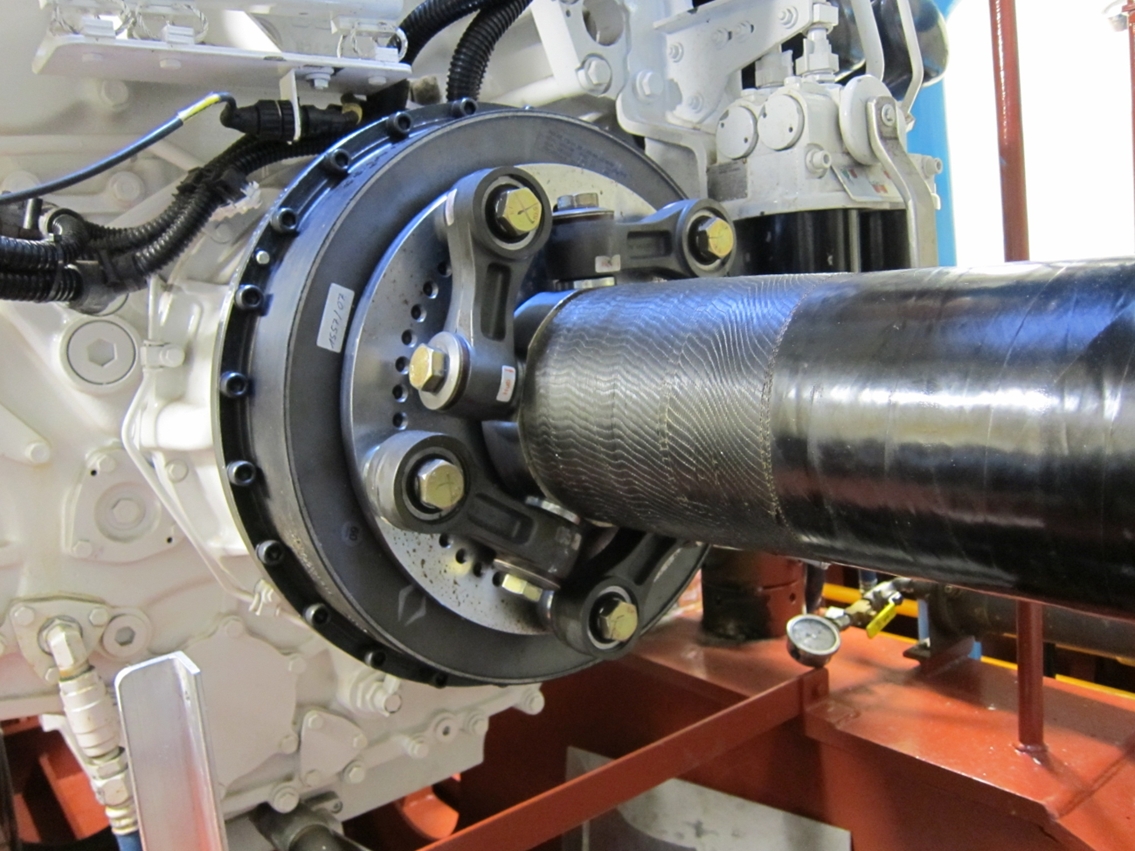

CENTAFLEX-D: coupling often used for generatorsets and diesel driven pumps

Available in various flange connections. Also available in various hub lengths. The CENTAFLEX-D is a coupling that falls into the “medium stiffness” category. In other words; the twisting angle under torque is approximately three to five degrees. Normally, this coupling is used for drives with a so-called overcritical area. This means that the operating speeds are above the main resonant speed. Therefore, the inertia of the secondary part must not be too low. Such conditions are commonly seen in generator and pump sets, for example. The coupling is suitable for flanged and non-flanged mounting of floating and driven part.

- Simple, robust, safe to use, compact, maintenance-free and spin-through protected.

- Generously dimensioned, low stress value, where the rubber is loaded only by pressure and well cooled by internal air flow. By using rubber elements with different hardnesses, in combination with the progressive spring characteristic, the optimum rigidity can be achieved.

- Vibration and shock isolation.

- Easy assembly, also for so-called monoblock constructions. Here the floating and driven part form one unit and the coupling is easy to mount.

- A wide range of all possible motor and generator connections is available from stock.

- Available under approval.

-

CENTAMAX: solid rubber coupling with outer teeth, a.o. for diesel engines

The Centamax is a robust coupling with high rotational elasticity and highly reliable construction for the transmission of high torques with compact dimensioning. Characterized by high rotational elasticity with a linear characteristic. Dampens rotary vibrations and bumps and compensates for axial, radial and angular displacements. Effectively ventilated, with high reliable power loss. In silicone version also insensitive to oil and to higher temperatures. Axial plug-in for easy assembly. With flywheel connections with SAE. Also available for non-standardized flywheels and pass-through.

Applications

- Pump distribution gearbox

- Screw compressor

- Boat drives

- Heat pumps

- Generators

- Locomotives

- Gyro

- Ships

Features

- Plug-in

- Backlash-free

-

CENTAX - SEC: rubber coupling ring with steel mounting flanges for the toughest applications

The CENTAX-SEC constitutes the top range of the CENTA program. These highly elastic couplings find their application in almost all possible diesel powered units, from marine propulsion plants to powerplants and from trains to agricultural vehicles. The basic element is formed by a closed rubber ring with a vulcanized steel mounting flange on both sides. This concept has proven to be virtually unbreakable.

The CENTAX-SEC coupling is tailor-made for your application. The torsional rigidity is by means of multiple elements mounted in series, possibly using parallel mounting. This in combination with the different rubber hardnesses in which the elements are available, offers an almost unlimited variety of torsional properties. In addition, the elements can be coupled with various connection parts, including single or double membrane systems and/or the superelastic limiter system.

The CENTAX-L is the absolute topper within the CENTAX-SEC range. The lenticular system has created a coupling that allows large displacements in all directions radially, axially and angularly, with particularly low reaction forces. This makes the CX-L particularly suitable for coupling elastically arranged motors.

- highly elastic

- compensation of high axial, radial and angular misalignments

- Modular design, many installation variations possible

- many application possibilities

-

CENTAFLEX-H: rigid coupling for multiple diesel-driven hydraulic pumps

The CENTAFLEX-H is a rugged, pluggable, relatively rigid coupling that is always undercritical selection. The CF-H is also resistant to oil and high temperatures, specifically designed to drive diesel-driven hydraulic pumps coupled to the engine through the flywheel housing. Construction form 4 has an integrated flywheel adaption flange, conforming to SAE 10, 11½ and 14 inches. Many variants, called pump adaptation plates, designed for mounting hydraulic pumps to engine flywheel housings are also available. The hubs are available with all possible spline types and with the well-known Centaloc system.

- High performance with compact dimensioning.

- High torsional stiffness, preventing small misalignments.

- Dampens vibrations.

- High permissible rotation speeds.

- Extremely high temperature resistance.

- Oil resistant.

- Easy, pluggable assembly.

- Free of axial forces.

- Maintenance-free.

- Optimal price/performance ratio.

-

CENTAFLEX-K: rigid plastic coupling for a diesel-driven hydraulic pump

THE CENTAFLEX-K Couplings are rotationally rigid and suitable for driving hydraulic pumps and similar applications with low inertia. Here, rotation is undercritical so that the drive is free of damaging resonance in the applied speed range. The hubs can be equipped with the patented CENTALOC clamping system. With this clamping system, the hub can be mounted backlash-free on spline shafts so that “fretting” cannot occur. The hubs can be adjusted to any length and shape. The CENTAFLEX-K features varied connections for both standardized and non-standardized SAE flywheels.

- Compact, lightweight, robust.

- Reliable, long service life.

- Oil resistant.

- High torsional rigidity.

- Short installation length.

- Easy mounting.

- Available from stock.

- Excellent price/quality ratio.

-

CENTAFLEX-X: rigid plastic coupling for subcritical applications

The CENTAFLEX-X is directly derived from the CENTAFLEX-A, but is manufactured in plastic instead of rubber. The dynamic torsional stiffness is therefore very high. The CF-X has a specific area of application and particularly excels due to the bending elasticity of the blades, making it very flexible axially and cardanically. Due to the choice of materials, the coupling is resistant to oil and high temperatures.

- high torsional rigidity

- very flexible axially and cardanically

- resistant to oil and high temperatures

We like to share our thoughts with you

There is an optimal coupling for each specific installation. Finding the right coupling for your installation is therefore a matter of understanding the specifications and characteristics of your installation. Our experienced experts will be happy to ask you a few questions about your installation so that together we can find the optimal coupling.

Looking for technical support from our specialist?

Suppliers & Brands

Related Products

Rigid Steelflex Couplings from Falk by Rexnord Regal

Bellows couplings from Rexnord Regal

Slip clutches and chain clutches from Cross and Morse

Miniature couplings from SDP/SI