With Centaflex-A, you can easily find the perfect coupling

The well-known Centaflex-A elastic coupling is known for its strength and long service life. And because of its wide variety of designs, the Centaflex-A can be used on a very wide spectrum of applications.

Our handy fill-in-the-blank document makes it easy to find the right version for your installation.

Easily choose the right version

One of the major advantages of the robust Centaflex-A elastic coupling is the great diversity of versions in which this coupling is available. Of course, this makes it important to know exactly where your specific needs lie if you want to install a new Centaflex-A coupling in your installation. To help you easily find the right coupling we have prepared a handy document for you in which the correct specifications can be easily selected.

Choosing the right elastic element

The elastic element is the distinguishing component of the Centaflex-A. Choosing the right elastic element is therefore the basis for finding the right coupling. If you only need a new elastic element because it needs to be replaced, for example, it is important to know the correct build size, hardness and type 0 or S.

Construction method, hub design and variant with steel shafts

In addition to filling out specifications for replacing the elastic element, we can also assist in finding the right specifications for the construction method, hub and possibly a variant with steel shafts.

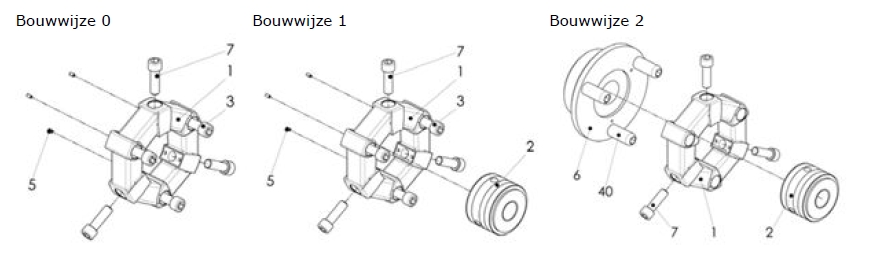

The different construction methods

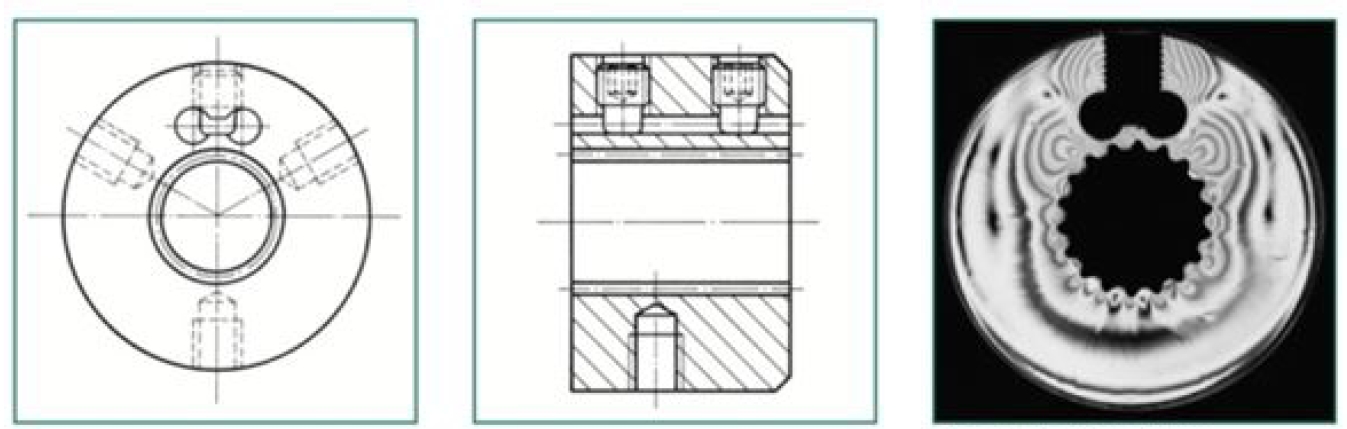

By choosing the right construction mode, we know immediately where your needs lie. As you can see in the drawing below, construction mode 1 and 2 are extensions of construction mode 0, the basis of the Centaflex-A.

- Construction mode 0 (zero) is just the elastic element.

- Construction mode 1 is the elastic element plus the hub.

- Construction mode 2 is the elastic element with hub flange and hub.

Hub design

The hub in construction mode 1 and 2 can be supplied in different ways. It can be with a normal or tapered shaft with keyway, with a taper lock, with a spline in SAE or another standard. For this, there is usually a Centa drawing number that exactly describes the scope of delivery.

The hub can also be supplied with the patented Centa lock system. This Centa lock system consists of two-parallel drilled holes that ensure better stress distribution. See diagram below.

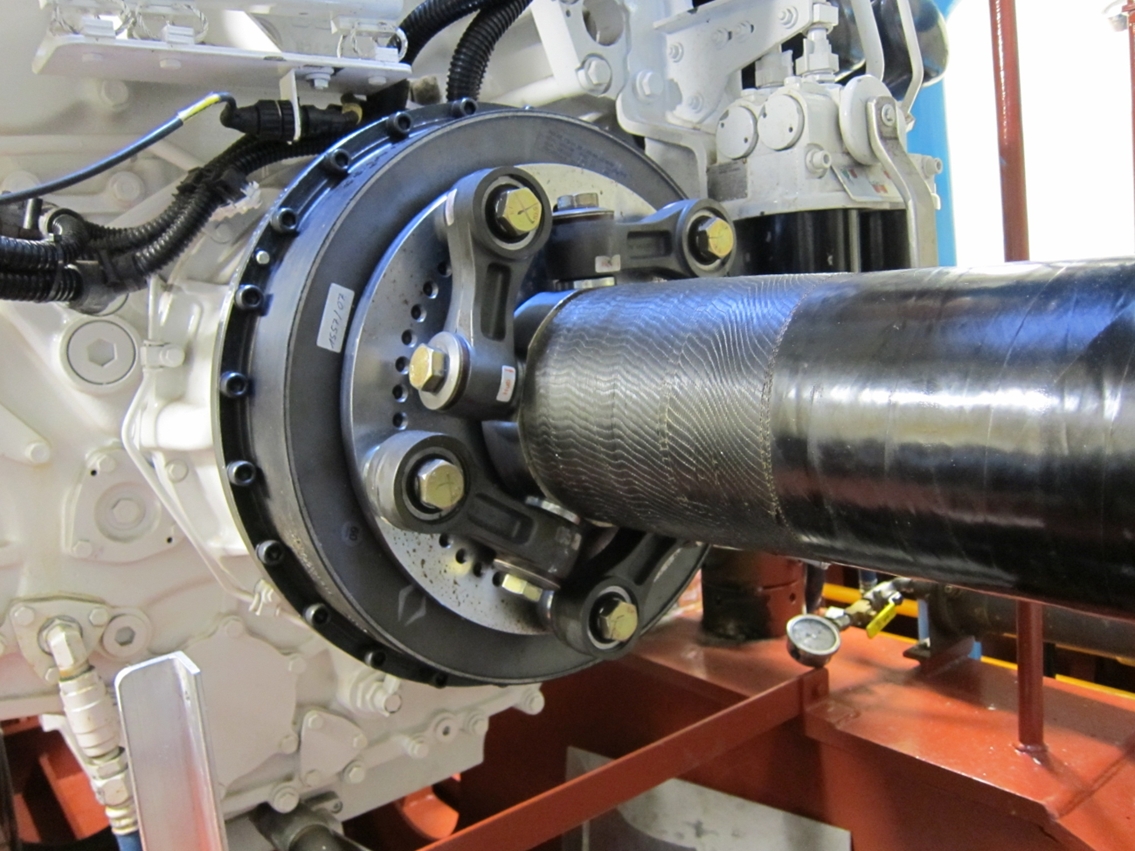

Variants G and GZ with steel shafts

Centa also has two Centaflex-A couplings combined with flanges and with steel shafts, e.g. for vibrating tables, buses, industrial grass machines, pump drives, fans, conveyors, parallel running spindle systems and motor drives. It exists in a G version and for speeds above 1500 rpm there is a special GZ version with additional support bearings.

Marine versions

The Centaflex-A is also used in smaller ships in combination with a support bearing to absorb vibrations from the propeller. See our special marine brochure for this.

Need technical advice from our specialist?

Suppliers & Brands

Downloads

Related Products

Couplings

Couplings from Centa

Rigid Steelflex Couplings from Falk by Rexnord Regal

Bellows couplings from Rexnord Regal

Slip clutches and chain clutches from Cross and Morse