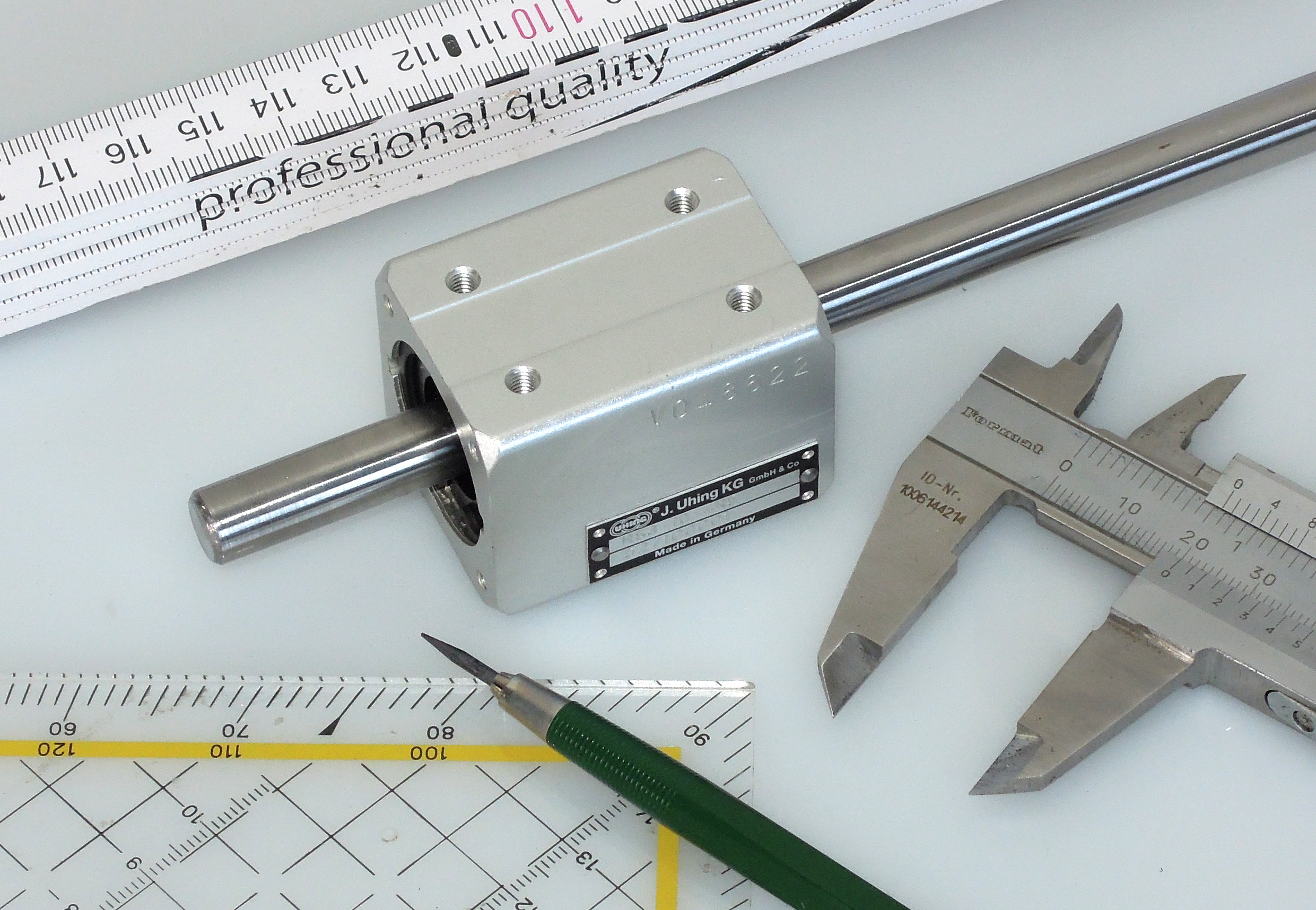

UHING RS linear drive nut is now available with a stainless steel body.

27 November 2024

At Caldic Techniek Belgium, we offer solutions that continuously respond to the high demands of our customers. The UHING RS linear drive nuts are now also available with a housing in stainless steel.

UHING RS linear drive nut is now available with a stainless steel body.

- Stainless steel housing

Thanks to this stainless steel version (1.4401), the housing is now even more resistant to an aggressive environment and intensive cleaning. This makes our linear drive nuts ideal for applications where hygiene is extra-important, such as food or pharma. The stainless steel housings are available for shaft diameters of 10, 15 and 25 mm. Other shaft diameters are available on request. - Surface roughness

A surface roughness of 0.8 micrometres is possible. - Grease

In terms of lubrication, we recommend Rivolta F.L.G HF-2 grease. We will be happy to quote for this. - Temperature

Ambient temperatures up to 50°C are no problem. If you would like to use the RS units at higher temperatures, we would be happy to discuss this with you. - Wipers We can fit RS units with wipers on the shaft as well as with grease nipples. The wipers are not 100% tight.

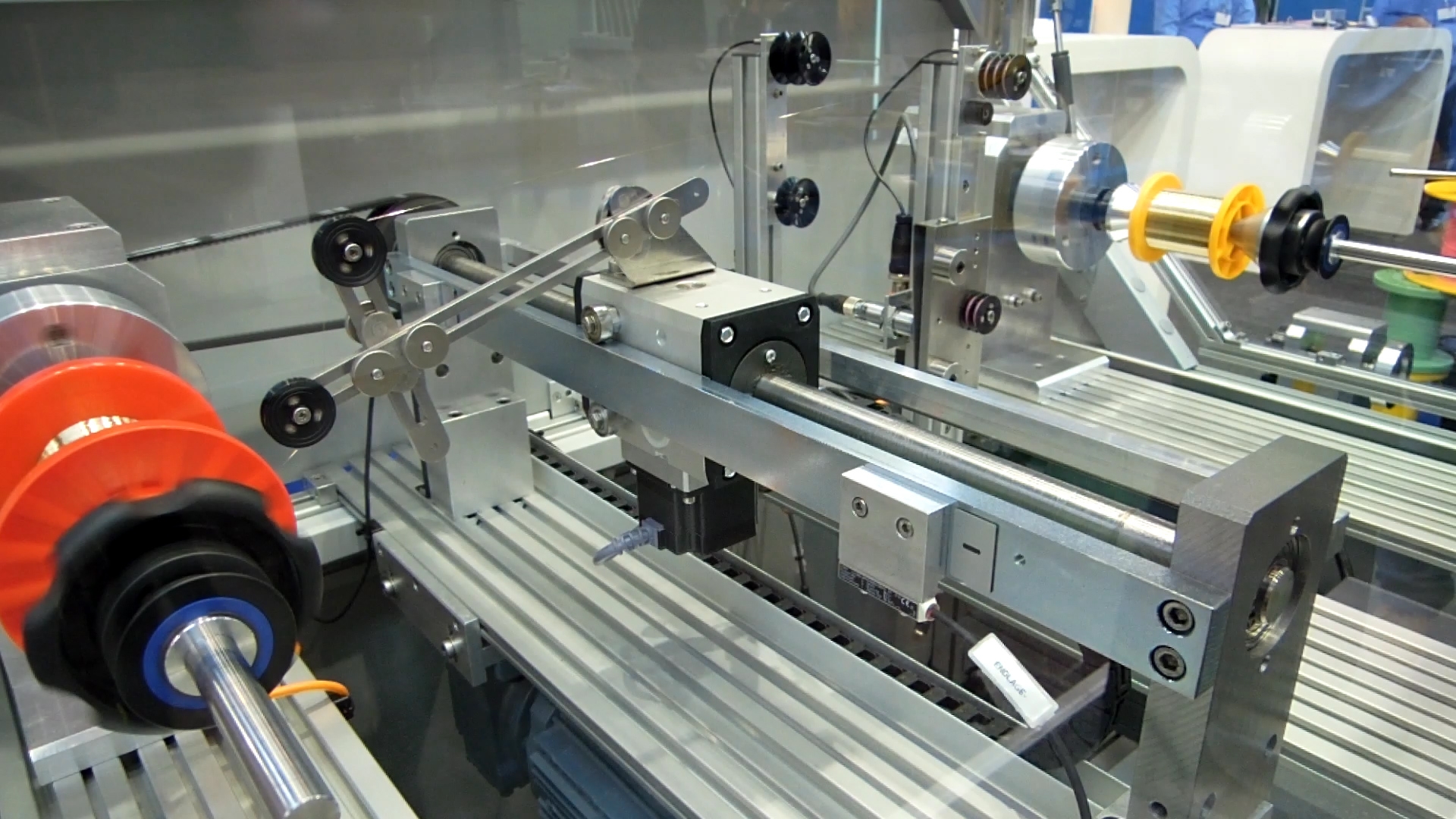

What can you do with UHING RS linear drive nut ?

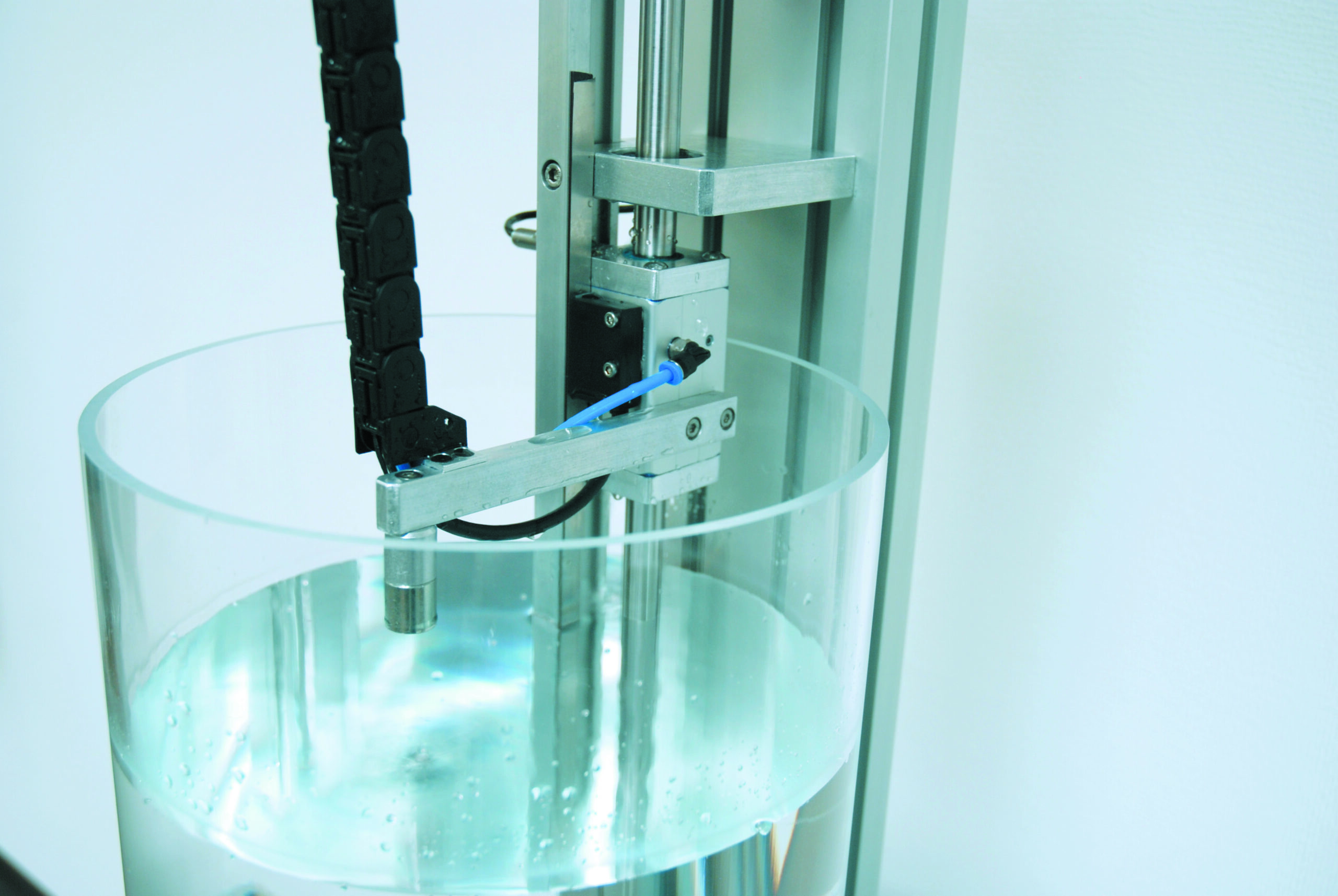

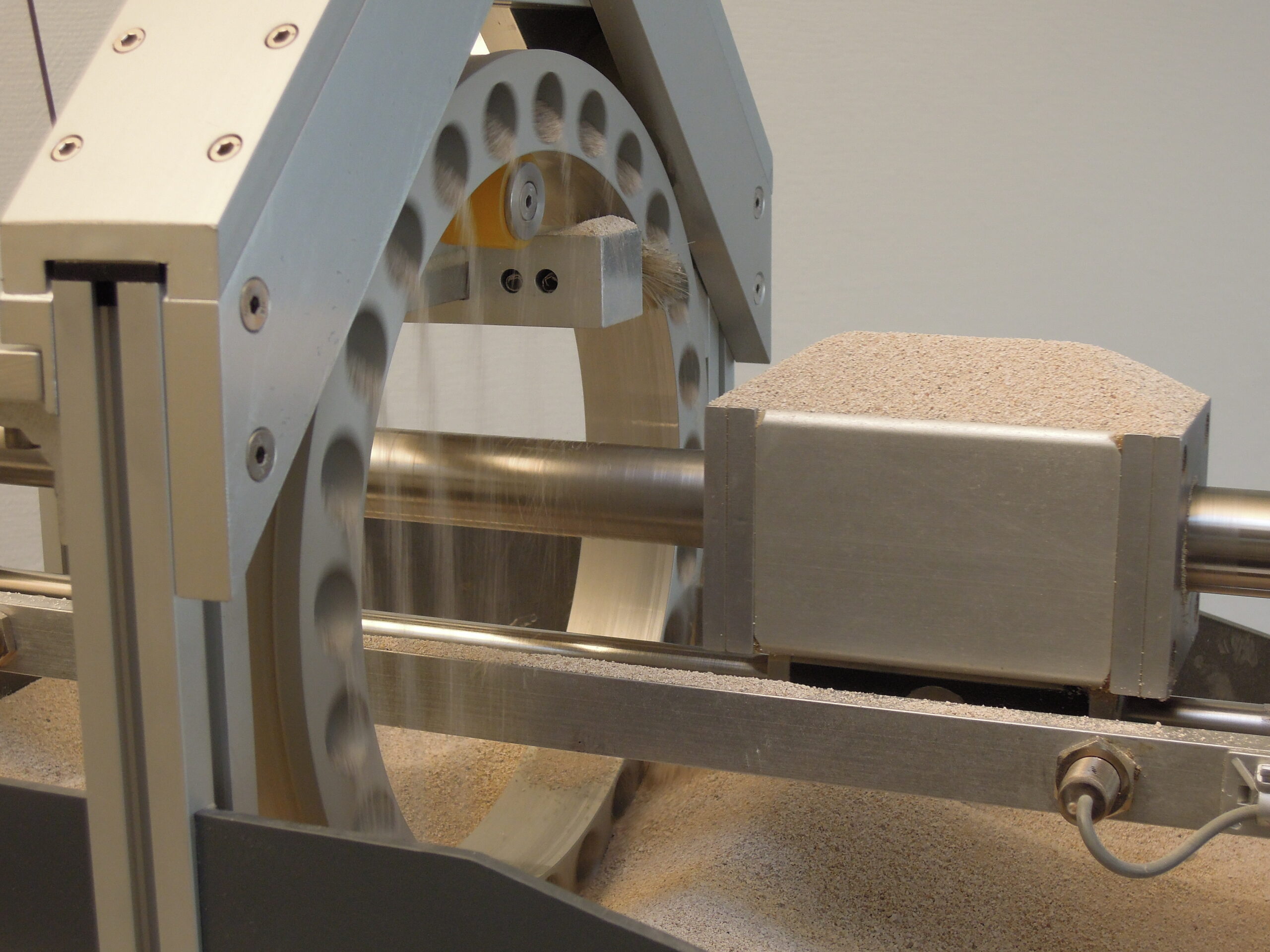

A UHING RS nut contains 3 or 4 bearings. 1 or 2 of those bearings are machined on the inside so that they can push at an angle on a smooth shaft. As a result, we are going to create a lateral displacement. (Archimedes’ screw movement) . Big advantage is that this is a smooth shaft without spirals or grooves. So very easy to keep clean and low maintenance. There are applications where the RS linear drive nut passes through a sand curtain (see picture). But an RS can also be used, for example, for immersion applications in water (see picture).

More information and support

Caldic Techniek Belgium is your specialist for UHING’s high-quality linear systems and offers comprehensive support. Contact our specialists for advice.

Any questions about UHING

Contact one of our colleagues